Sargent Aerospace & Defense

Contact Us

Send us a message

Note: Messages will be sent to Sargent Aerospace & Defense only

About Sargent Aerospace Hydraulics

The Sargent Story

The Sargent Story

In 1920 Sumner Benedict Sargent sold a patent he had obtained to the oil industry in order to found the Sargent Engineering Company. The first factory was a 800 square foot shed in Sargent’s back yard in Huntington Park, CA. In the 1940s the Sargent Engineering Company’s business shifted to aerospace and defense to support the growing WWII effort. Sargent’s unwavering focus on solving difficult application problems via an innovative engineering approach led to The Sargent Engineering Company becoming a highly regarded, and respected partner in the aerospace and defense industry.

Since its humble beginnings in 1920 The Sargent Engineering Company has become Sargent Aerospace and Defense and has grown into one of the world’s leading suppliers of highly engineered, specialty hydraulic actuation products serving the aerospace, defense, and space markets.

About Sargent

Today, Sargent resides in a facility in Tucson, AZ, and as part of the RBC Bearings, Sargent Aerospace and Defense continues Sumner Benedict Sargent’s legacy of solving difficult problems via a mission of making the challenging a reality, delivering high quality products and services that meet customer requirements and exceed customer expectations. One of Sargent’s top priorities is to develop close working relationships with our customers, and become part of their engineering problem solving process.

Sargent Aerospace and Defense’s Tucson facility serves as RBC Bearings’ center of excellence for commercial and military hydraulic actuation design, qualification/testing, and hydraulic component manufacturing and assembly for aerospace OEMs and aftermarket. The Sargent Tucson facility is ISO 9001:2015 and AS9100D accredited as well as NADCAP certified for non-destructive testing (NDT).

Experts in the Industry

Sargent Aerospace and Defense prides itself on being the company that solves our customer’s toughest design problems. Sargent’s highly experienced team provides innovative and out of the box thinking to solve aerospace’s most difficult hydraulic actuation applications. Sargent hydraulic products cover a wide range of applications on platforms such as the KC-135 tanker, Boeing 737, and F-35 Joint Strike Fighter.

Click on the link below for more information about Sargent Aerospace and Defense’s full range of hydraulic actuation products and capabilities.

www.sargentaerospace.com

About Sargent Marine Hydraulics

The Sargent Story

The Sargent Story

In 1920, Sumner Benedict Sargent sold a patent he had obtained to the oil industry, funding the start of the Sargent Engineering Company. The first factory was an 800 square foot shed in Sargent’s back yard in Huntington Park, CA. In the 1950s The Sargent Engineering Company’s engineering capabilities and innovative problem solving approach led the United States Navy to adopt lightweight aluminum components in place of traditional steel components for the nuclear powered submarine fleet.

Since its humble beginnings in 1920, The Sargent Engineering Company has become Sargent Aerospace and Defense and continues to proudly support the United States Navy’s nuclear submarine fleet via a portfolio of complex hydraulic valves utilizing Sargent’s proprietary quiet technology. Sargent currently supports five in-service classes of submarines in an OEM and aftermarket capacity, producing over 140 hydraulic valve designs on new Virginia and Columbia Classes, as well as superior fleet support with a full range of maintenance and overhaul capabilities in support of Los Angeles, Ohio, Seawolf, and Virginia Classes.

Products

Marine Hydraulic and Pneumatic Valvles, Sargent Aerospace and Defense

Sargent has been designing and manufacturing hydraulic valves for the US Navy since 1950. Sargent’s valve designs are specifically engineered for the rigors of surface and subsurface marine environments.

Marine hydraulic valves can be designed and manufactured in a variety of configurations:

- Electro-Hydraulic Servo Valves

- Pressure Reducing Valves

- Directional Control Valves

- Restrictor Valves

- Flow Control Valves

- Air Vent Valves

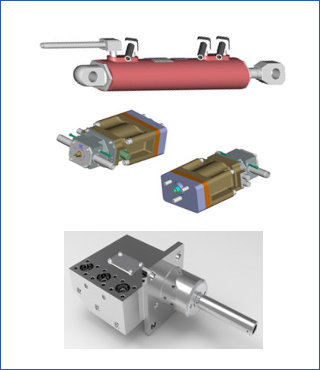

Marine Rotary and Linear Actuators, Sargent Aerospace and Defense

Sargent has been designing and manufacturing hydraulic components for the US Navy since 1950. Sargent’s marine actuator products are specifically designed for the rigors of marine environments. Sargent leverages its century of experience designing hydraulic products when designing actuators for even the most demanding applications.

Sargent’s marine actuator line can be found in the following applications:

- Door actuation

- Ramp actuation and rotation

- Mast positioning

- Hatch positioning

- High or low load capacity

- Various stroke lengths

- End of stroke mechanical cushioning

- Quiet operation

- Exposure to harsh environments

Marine Duplex Pumps, Sargent Aerospace and Defense

Sargent has been designing and manufacturing hydraulic components for the US Navy since 1950. Sargent’s duplex pump products are specifically designed for the rigors of marine environments. Sargent leverages its century of experience designing hydraulic products when designing pumps for even the most demanding applications.

Sargent’s duplex pump line can be found in the following applications:

- Wastewater handling

- Drain / discharge systems

- Desalination systems

- Efficient

- Low or high flow rate designs

- Resistance to harsh environments

- Quiet operation

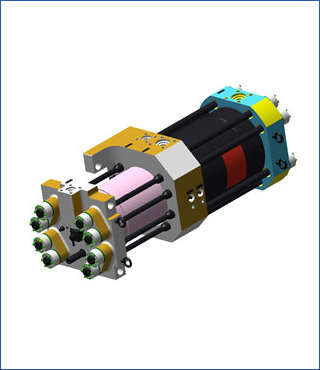

Hydraulic Actuators, Sargent Aerospace and Defense

Hydraulic actuators play a critical role on various aircraft system. From landing gears to outer doors, hydraulic actuators are the tool used to move heavy objects or surfaces exposed to high loads. Sargent has been supporting the aerospace industry with hydraulic actuators that perform for the life of the aircraft, or spacecraft, and routinely support ultimate loads in excess of 50,000 lbs.

Snubber rings can be Sargent utility actuators in aerospace applications:

on landing gear used on:

- Landing gear extend, retract, downlock, uplock

- External doors

- Thrust reversers

- Wing fold / Rotor fold

Actuator Benefits include:

- Auto or manual mechanical locking

- Lock and position sensing

- Rate of motion control

- End of stroke damping

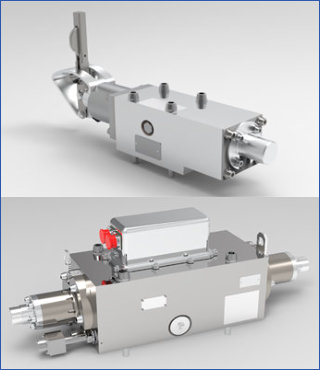

Hydraulic Valves - Sargent Aerospace and Defense

Hydraulic valves can be found throughout modern aircraft and are required to control hydraulic actuators. Sargent specializes in designing multi-position directional control valves. Sargent valves are designed to perform for the life of the aircraft or spacecraft.

Sargent hydraulic valve are commonly found in:

- Landing gear systems

- External doors

- Thrust reversers

- Rotor and wing fold systems

- Flow control and metering

- Directional control: 3000-5000 psi systems

- Multi-position: 2,3,4 way designs

- Pressure reducing designs available

- Swivel designs available

Hydraulic Filter Manifolds - Sargent Aerospace and Defense

Sargent designs and manufactures integrated filtration products for aircraft and spacecraft fluid hydraulic systems. Sargent’s manifolds are designed to operate efficiently in high pressure and flow environments while offering optimum protection from contaminants in the hydraulic fluid.

Sargent hydraulic valve are commonly found in:

- Aircraft hydraulics systems

- Spacecraft hydraulic systems

- Business jet hydraulic systems

- Rotorcraft hydraulic systems

- Integrated filter element

- Integrated bypass valves

- Weight saving designs

- On board pressure transducers and/or differential pressure indicators

Hydraulic Accumulators and Reservoirs, Sargent Aerospace and Defense

Hydraulic accumulators play a critical role in aerospace hydraulic systems by acting as a storage reservoir and transient buffer for the hydraulic system. Sargent’s gas charged piston accumulators are designed to absorb pressure transients from upstream sources and stabilize flow and pressure to downstream components thereby maintaining operational performance in the system.

Sargent hydraulic accumulators are commonly found in:

- Aircraft hydraulic systems

- Spacecraft hydraulic systems

- Business jet hydraulic systems

- Rotorcraft hydraulic systems

Hydraulic Accumulators characteristics include:

- Designs optimized for light weight

- Capable of operating in high pressure environments

- Piston can be designed with multiple seals

- Maintenance free

- Can be designed with pressure transducers

Hydraulic Dampers - Sargent Aerospace and Defense

Vibrations in aerospace systems can lead to system failures and it important to control vibration. Sargent’s hydraulic dampers are designed to control vibration and are designed and manufactured based on Sargent’s heritage in hydraulic actuation. Sargent’s patented rotor head damper features adaptable damping characteristics and proprietary bearing liner system that significantly reduces weight, increases service life, and system reliability even in harsh environments where other dampers fail.

Sargent hydraulic dampers are commonly found on:

- Rotor heads

- Nose landing gear

- Adaptable frequency helicopter rotor head damper

- Lightweight designs

- Long life rod end bearings

- Increased durability and long service life on rotor head

Hydraulic Relief Valves - Sargent Aerospace and Defense

Sargent relief valves are designed and manufactured to precise standards and protect sensitive components from overpressure. Relief valves are generally installed downstream of hydraulic flow/pressure sources and/or regulators to protect the system from a malfunction.

Sargent relief valves are commonly found in:

- Aircraft hydraulics systems

- Spacecraft hydraulic systems

- Rotorcraft hydraulic systems

- Wide range of operating pressures

- Stable flow and low pressure drop

- Low internal leak rates

- Lightweight

- Variety of mounting options available

- Variety of seal materials available

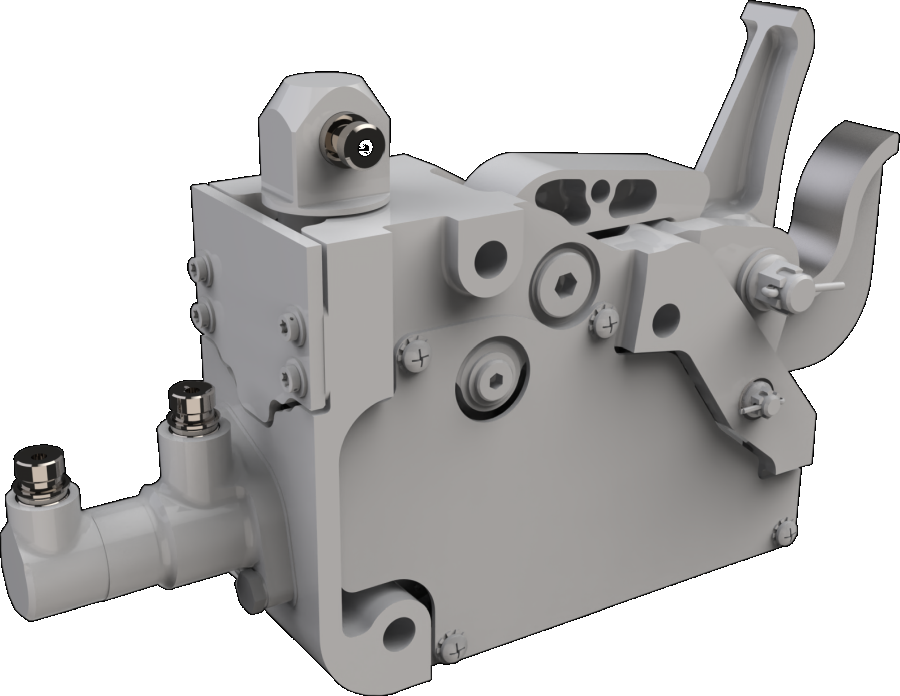

Hydraulic Uplock / Downlock, Sargent Aerospace and Defense

Landing gears are critical systems in any aerospace platform. When the gear is stowed or deployed it is critical that the gear stays in that position, even if there is a failure in the hydraulic system. This is where uplock and downlock assemblies play a critical role. By leveraging manufacturing, structure knowledge, and hydraulic design selection, Sargent can support manufacturing of an entire assembly saving customers from having to source critical components from multiple suppliers.

Sargent uplocks / downlocks are commonly found in:

- Aircraft landing gear

- Spacecraft landing gear

Uplock / Downlock characteristics can include:

- Hydraulic component integration

- Status indication (depending upon design)

- Weight optimization

Location(s)

Locations (click on Directions):

Tucson, Arizona

5675 West Burlingame Road, Tucson, AZ 85743Inquiries@SargentAerospace.com Phone: (520) 744-1000

Toll Free: (800) 230-0359

Fax: (520) 744-9494