RBC Industrial Division

Contact Us

Send us a message

Note: Messages will be sent to RBC Industrial Division only

About RBC - West Trenton

RBC Bearings West Trenton is the original location of the RBC Bearings Corporation with a history that dates back to 1919. The West Trenton facility shown was built in 1950 has been the home of many RBC innovations. In that 70-year period, RBC has been the leader in the development of spherical plain bearings, and is the original patent holder on many innovative designs of that product. The RBC West Trenton facility produces spherical bearings with a size range from 4 inch to a maximum of 24 inch outer diameter. The spherical plain bearing products produced at this facility service the mining, construction, oil & gas, material handling, and agricultural markets.

RBC Bearings West Trenton is the original location of the RBC Bearings Corporation with a history that dates back to 1919. The West Trenton facility shown was built in 1950 has been the home of many RBC innovations. In that 70-year period, RBC has been the leader in the development of spherical plain bearings, and is the original patent holder on many innovative designs of that product. The RBC West Trenton facility produces spherical bearings with a size range from 4 inch to a maximum of 24 inch outer diameter. The spherical plain bearing products produced at this facility service the mining, construction, oil & gas, material handling, and agricultural markets.

RBC West Trenton is also the current home of the RBC Nice Ball Bearings product. The Nice Ball Bearing Company was originally founded in Philadelphia in 1902. RBC Bearings relocated Nice Bearing to the West Trenton facility from Kulpsville, Pennsylvania in 2006. The Nice line of ball bearings serves many industries including material handling, packaging equipment, agricultural, and aluminum beverage can production.

RBC Bearings West Trenton also produces needle roller bearings used in the rotor head of the Boeing CH-47 and previously the CH-46 helicopters since the inception of these aircraft in the early 1950’s.

RBC Bearings West Trenton is the product design and applications center for the RBC Bearings Industrial Division. RBC Bearings also has extensive product endurance and qualification test lab capabilities to assist our customers in validating custom designed bearing solutions for their demanding applications.

Our Products - RBC - West Trenton

Spherical Plain Bearings, RBC Bearings

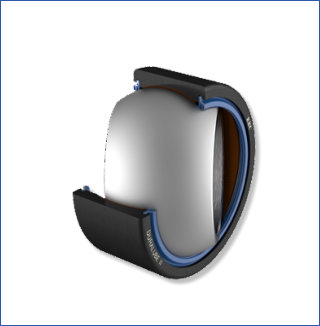

RBC Bearings has been the pioneer in spherical plain bearing technology since inventing the fractured outer race design many years ago. Since that time, RBC has continued to introduce industry leading innovations. RBC’s spherical plain bearings are available in both inch and metric sizes, sealed and non-sealed, with inner dimensions ranging from ½ to 12 inch and 12 to 320 millimeters.

RBC Bearings Product Innovations

|

|

|

|

Key Features

- Intended for slow oscillation/rotation & high load applications

- Provides duel wear paths (bore/shaft & ball/race surfaces)

- Prevents edge loading due to misalignment.

- More tolerant to impact loads and contamination.

RBC Bearings Manufacturing Facilities: West Trenton, NJ & Hartsville, SC

DuraLube ™ II, RBC Bearings

RBC’s DuraLube™II maintenance free spherical plain bearing provides reliable, grease free operation through the use of highly engineered PTFE self-lubricating liner systems to reduce internal friction between surfaces. DuraLube ™ II spherical plain bearings are available in both inch and metric series, bore ranges from ½ to 12 inch and 12 to 320 millimeters.

PTFE Liner Options

- DuraLube™ Standard

- DuraLube™ Plus

- DuraLube™ Ultra

- TriLock™ Seal

|

|

- Ensure lubricant remains in the load zone

- Reduced operation costs / no costly lubrication systems

- Provides greater ‘power density’ and reliable operation in more extreme environments

- Reduced clearance / good for reversing load applications

RBC Bearings Manufacturing Facilities: West Trenton, NJ & Hartsville, SC

NICE® Ball Bearings, RBC Bearings

RBC Bearings produces easy to use inch series ball bearings in various sizes. Configurations include Ground, Semi-Ground, and Unground bearings.

Applications

- Food Processing Equipment

- Medical Equipment

- Material Handling

- Agriculture

- Ability to carry radial and axial loads.

- Lower friction than standard bearings.

- 1600™ Series, 7500™ Series

- 7600™ Series, ER™ Series

- Detailed inspection sheet

- 6900™ Series

- 3000™ Series

- 400 ™Series, 500™ Series, 600™ Series , 5000™ Series

- SRM™ Series, FSRM™ Series, RF™ Series

RBC Bearings manufactures these ball bearings domestically in West Trenton, NJ

NICE® Insert Bearings, RBC Bearings

Insert Bearings are used for mounting on shafts without the need for shoulders, locknuts, or adapters. The bearing is locked in place through either set screws to the shaft or with a flange design to be retained in a housing.

Applications:

- Conveyer Systems

- Handling Systems

- Packaging

- Textile Equipment

- The various locking methods enable quick and easy mounting of the bearing.

- With different sealing solutions available, the insert bearing provides a long service life for many applications.

- Available in MAX3TM steel

- Reduced vibrations and noise levels.

- 3000™ Series, ER™ Series, 7600™ Series

- 7500 ™ Series, FSRM™ Series, RF™ Series

- 6900™ Series, 7600™ Series, ER™ Series

RBC Bearings manufactures insert bearings domestically in West Trenton, NJ

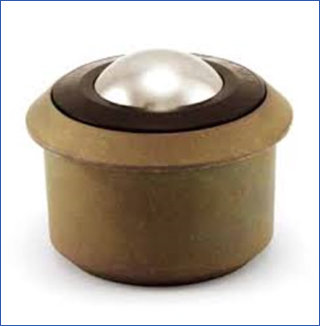

NICE® Ball Transfer Units, RBC Bearings

A Ball Transfer Unit is a multi-directional material handling unit that assists with the movement of heavy loads.

Applications:

- Luggage Delivery Carousels

- Air Cargo

- Robotics

- Glass & Metal Manufacturing

- Outperforms other ball transfer units on the market

- Gives ability to convey materials in any direction with minimal friction or interface

- Patented design that improves load carry capability

RBC Bearings manufactures ball transfer units domestically in West Trenton

Pitchlign Heavy Duty Needle Roller Bearings, RBC Bearings

RBC Bearings has a series of heavy duty machined race needle roller bearings in size ranges of 1’’ to 12 ¼ ‘’ outside diameter.

Applications:

- Gear boxes and gear pumps

- Oil and gas rigs

- Cranes and hoists

- Specialty railroad equipment

- SJ Series – Single roller per pocket

- TJ Series – Two rollers per pocket offering 40% greater dynamic capacity

- Sealed and unsealed

- Eight different seal configurations available

- IR Series – Hardened and ground inner ring to take the place of a hardened and ground shaft

- ESJ Series – The SJ and IR come as one assembly

- Material Customized designs available upon request

About RBC - Hartsville

The RBC Bearings Hartsville, South Carolina facility, located at 2268 S 5th St, Hartsville, SC 29550, was opened in 1966. The facility has been through several modernizations since that time and today has the capability to produce a range of different bearing types with sizes ranging from 1-inch to 43-inches in outer diameter. A leading product produced at this facility is Cam Followers for a wide range of applications, including the innovative RBC Roller design that was invented by RBC Bearings in 1990. The RBC Bearings Roller design is a unique patented two-roller per path Cam Follower which allows for higher load capacity in a sealed for life configuration. It has been a problem solver for very demanding applications in the oil & gas, material handling, packaging, and aluminum beverage can industries.

The RBC Bearings Hartsville, South Carolina facility, located at 2268 S 5th St, Hartsville, SC 29550, was opened in 1966. The facility has been through several modernizations since that time and today has the capability to produce a range of different bearing types with sizes ranging from 1-inch to 43-inches in outer diameter. A leading product produced at this facility is Cam Followers for a wide range of applications, including the innovative RBC Roller design that was invented by RBC Bearings in 1990. The RBC Bearings Roller design is a unique patented two-roller per path Cam Follower which allows for higher load capacity in a sealed for life configuration. It has been a problem solver for very demanding applications in the oil & gas, material handling, packaging, and aluminum beverage can industries.

RBC Bearings Hartsville is also the main production facility for industrial Spherical Plain Bushings between the sizes of 1-inch and 4 ½-inch outer diameter, produces self-lubricating lined spherical plain bushings to provide maintenance free capability. Maintenance free bearings is a strong emerging technology in the mining and construction industries serviced by this product.

RBC Bearings Hartsville is also the main production facility for RBC’s heavy bearings offering in tapered roller, tapered thrust, and cylindrical bearings from 12-inch to 43-inch diameter. This offering includes use of RBC’s unique MAX3™ steel technology that allows for increased load capacity and extended bearing life. Heavy cross section bearings produced at this facility service the oil & gas industry in fracking pumps, top drive, and power swivel applications. RBC’s offering of large diameter taper roller bearings is also used for mining electric wheel motor applications.

Our Products - RBC - Hartsville

Needle Roller Cam Follower, RBC Bearings

Needle Roller Cam Follower is a bearing assembly that contains rolling elements (needle rollers) designed to follow tracks or cams and in a wide range of linear motion systems.

Needle Roller Cam Followers are used in a wide variety of industries and applications, including:

- Packaging

- Material Handling

- Can Making

- Agriculture

- Self contained assembly for ease of installation in an application

- Low rolling resistance

- Heavy outer ring cross section to absorb shock loads

- Eliminates noise during operation

- High Dynamic and Static load carrying capability

RBC Roller® Cam Followers, RBC Bearings

RBC Bearings Roller® Cam Followers offer the same benefits as the Needle Roller Cam Follower, but has much more to offer. The RBC Bearings Roller is the problem solver Cam Follower.

RBC Bearings Roller® Cam Followers are a drop in replacement for Needle Roller Cam Followers and are used in the same applications and industries, including:

- Oil / Gas

- Construction / Mining

- Can Making

- Bottle Cap Making

- Dual Row Cylindrical Roller which increases dynamic load capacity provides increased fatigue life.

- Contacting Lip Seals offer positive retention of lubrication and exclusion of contaminants.

- Large Grease Reservoir helps to ensure “Lube for Life” performance.

- Precision guided roller provides up to 50˚F cooler running temperature.

Tapered Roller Bearings, RBC Bearings

Tapered roller bearings support heavy operating radial and axial loads. Single and double row sizes are available up to 40 ‘’ outside diameter.

Applications

- Mining trucks

- Electric rope shovels

- Draglines

- Oilfield mud pumps

- 52100 Thru-Hardened Steel

- 8620 Case Carburizing Steel

-

- Para-premium – improved cleanliness

- RBC Bearings MAX3 ® - Ultra cleanliness / 3x Life

- Super finished rollers & raceway

- Lifting holes for ease of handling

- Detailed inspection sheet

- Pin type construction or stamped steel cage

- Case carburized steel

- RBC Bearings MAX3 tm - Ultra cleanliness / 3x Life

- Customized designs available upon request

- Mining Trucks

- Electric Rope Shovels

- Draglines

- Oilfield Mud Pumps

Large Tapered Roller Thrust Bearings, RBC Bearings

Large tapered roller thrust bearings are available in sizes up to 40’’ outside diameter. These highly engineered bearings are designed for demanding applications operating in harsh environments.

Applications:

- Oil and gas top drives

- Extruder gearboxes

- Oilfield swivels

- Boring mill tables

- Lifting holes for ease of handling

- High shock load resistance

- Available in MAX3TM steel

- V-flat sizes

- Bronze or pin-type cages

- Customized designs available upon request

Cylindrical Roller Bearings, RBC Bearings

Cylindrical roller bearings handle heavy radial loads. Sizes available up to 40” outsidediameter.

Applications:

- Mud and frack pumps

- Steel and rolling mills

- Industrial gear boxes

- Industry Interchangeability

- Available in carburized and thru-hardened steels

- Available in MAX3TM steel

- World-class lead times

- One piece machined bronze cage

- Customized designs available upon request

Spherical Plain Bearings, RBC Bearings

RBC Bearings has been the pioneer in spherical plain bearing technology since inventing the fractured outer race design many years ago. Since that time, RBC has continued to introduce industry leading innovations. RBC’s spherical plain bearings are available in both inch and metric sizes, sealed and non-sealed, with inner dimensions ranging from ½ to 12 inch and 12 to 320 millimeters.

RBC Bearings Product Innovations

|

|

|

|

Key Features

- Intended for slow oscillation/rotation & high load applications

- Provides duel wear paths (bore/shaft & ball/race surfaces)

- Prevents edge loading due to misalignment.

- More tolerant to impact loads and contamination.

RBC Bearings Manufacturing Facilities: West Trenton, NJ & Hartsville, SC

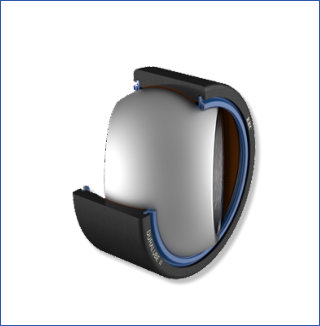

DuraLube ™ II, RBC Bearings

RBC’s DuraLube™II maintenance free spherical plain bearing provides reliable, grease free operation through the use of highly engineered PTFE self-lubricating liner systems to reduce internal friction between surfaces. DuraLube ™ II spherical plain bearings are available in both inch and metric series, bore ranges from ½ to 12 inch and 12 to 320 millimeters.

PTFE Liner Options

- DuraLube™ Standard

- DuraLube™ Plus

- DuraLube™ Ultra

- TriLock™ Seal

|

|

- Ensure lubricant remains in the load zone

- Reduced operation costs / no costly lubrication systems

- Provides greater ‘power density’ and reliable operation in more extreme environments

- Reduced clearance / good for reversing load applications

RBC Bearings Manufacturing Facilities: West Trenton, NJ & Hartsville, SC

Pitchlign Heavy Duty Needle Roller Bearings, RBC Bearings

RBC Bearings has a series of heavy duty machined race needle roller bearings in size ranges of 1’’ to 12 ¼ ‘’ outside diameter.

Applications:

- Gear boxes and gear pumps

- Oil and gas rigs

- Cranes and hoists

- Specialty railroad equipment

- SJ Series – Single roller per pocket

- TJ Series – Two rollers per pocket offering 40% greater dynamic capacity

- Sealed and unsealed

- Eight different seal configurations available

- IR Series – Hardened and ground inner ring to take the place of a hardened and ground shaft

- ESJ Series – The SJ and IR come as one assembly

- Material Customized designs available upon request

About RBC - Oklahoma

RBC Bearings acquired the Oklahoma facility, located at 5001 SW 20th St, Oklahoma City, OK 73128, in 2001. Since that time, RBC - Oklahoma has been focused on providing steering axle bearings for use in the Class 5 through 8 truck market. As a large market share player in this product space, RBC - Oklahoma provides these products to the largest truck axle builders in North America and South America. RBC - Oklahoma also services the aftermarket for truck axle repair and overhaul through the heavy duty parts distributor network. RBC Oklahoma is also the design and testing center for taper thrust bearings for axle applications.

RBC Bearings acquired the Oklahoma facility, located at 5001 SW 20th St, Oklahoma City, OK 73128, in 2001. Since that time, RBC - Oklahoma has been focused on providing steering axle bearings for use in the Class 5 through 8 truck market. As a large market share player in this product space, RBC - Oklahoma provides these products to the largest truck axle builders in North America and South America. RBC - Oklahoma also services the aftermarket for truck axle repair and overhaul through the heavy duty parts distributor network. RBC Oklahoma is also the design and testing center for taper thrust bearings for axle applications.

In 2020, RBC Bearings launched an innovative, patented design for a maintenance free kingpin for class 5 through 8 truck axles which eliminates the need for periodic re-greasing which provides reduced cost of ownership and increased uptime for customers.

In recent years, RBC Bearings has expanded the Oklahoma plant’s mission to include a heavy section roller bearings used in large fork truck applications.

Our Products - RBC Oklahoma

Tapered Thrust Bearing, RBC Bearings

Tapered thrust bearings utilize a full component of rollers to maximize load capacity and minimize roller skewing. RBC Bearings produces and stocks this product in sizes up to 3‘’ bore diameter.

Applications

- Class 8 steer axles

- Landing gear

Outside Diameter (OD) Size Range

- 1.901” – 5.265”

- 279.40mm – 1016mm

- Case hardened thrust washers and rollers

- Full Complement of rollers

- Tapered and cylindrical rollers available

- High thrust load and moderate speed applications

- Seals and grease styles available

- Sealed closure cup

- Customized designs available upon request

Outside Diameter (OD) Size Range

- 1.901” – 5.265”

- 279.40mm – 1016mm

- Proprietary self lubricating disk

- Sealed closure cap

- Greater torque in Air-ride steer axle applications

- Available in all Tapered Thrust Bearing Dimensions

Additonal Division Information

Location(s)

Locations (click on Directions):

West Trenton, New Jersey

400 Sullivan Way, West Trenton, NJ 08628RBCService@RBCBearings.com Phone: (609) 882-5050

Fax: (609) 882-5533