HEIM® Bearings

Contact Us

Send us a message

Note: Messages will be sent to HEIM® Bearings only

About HEIM® Bearings

Heim Bearings was founded in 1932 by Lewis Heim, the inventor of the “Heim Joint” (rod end). The original “Heim Joint” was an integral part of supporting US troops in WWII. This tradition continues today as Heim supplies bearings on key military platforms.

Heim Bearings was founded in 1932 by Lewis Heim, the inventor of the “Heim Joint” (rod end). The original “Heim Joint” was an integral part of supporting US troops in WWII. This tradition continues today as Heim supplies bearings on key military platforms.

In 1993, Heim was purchased by RBC Bearings, a leader in the world of highly engineered bearing products. Heim Bearings has a proven history of introducing new products to the market place. Today, Heim Bearings products are utilized to solve demanding performance applications on commercial and military aircraft, helicopters, armored military vehicles and tanks, and on a wide range of industrial applications.

Heim Bearings bearing products are made from a wide range of materials including aluminum, Inconel®, Stellite®, carbon steel, and corrosion resistant steels. Heim Bearings’ maintenance free Uniflon® self-lubricating liner technology is one of the best performing liner systems in the industry. When this proprietary self-lubricating liner technology is coupled with our patented sealing technology, these Heim bearing products outlast all others in the harshest and most demanding performance applications.

Heim Bearings is located in Fairfield, Connecticut, and has a dedicated, hardworking group of employees. With Heim’s strong engineering team, we are able to tackle our customers’ most challenging bearing applications, and Heim provides unmatched customer service levels. Heim Bearings is a multi-year Boeing Performance Excellence Award (BPEA) winning supplier.

Trademark Information

Inconel® is registered trademark of Inco Alloys International Inc., Corp. of Huntington West Virginia

Stellite® is a registered trademark of Kennametal Inc. of Latrobe, Pennsylvania

HEIM Manufacturing and Special Processes

About RBC Engineered Components

RBC Engineered Components was started in 1993 as a center of excellence for machining metal components to support RBC Bearings, a leader in the world of highly engineered bearing products.

RBC Engineered Components was started in 1993 as a center of excellence for machining metal components to support RBC Bearings, a leader in the world of highly engineered bearing products.

Today, RBC Engineered Components supports RBC Bearings sites with precision machining capabilities, and special processes. All of Engineered Components products are supplied to other RBC Bearings companies, but does not supply direct to customers. Over the past few years, RBC Bearings added key processes at Engineered Components to augment capacity relative to the existing supplier base for aerospace bearing products. Bringing these processes in-house also reduced throughput time for products being produced. Engineered Components is AS9100 approved and has gained NADCAP approvals for: Chemical Processing, and Heat Treating, and Boeing approvals for: Aluminum Pigment per BMS 10-85 and Dry Film per BAC5811 Type VIII.

Engineered Components is located at the RBC Bearings World Headquarters in Oxford, CT. We have a dedicated, hardworking employee base that is focused on engineered processes to support RBC Bearings. The workforce was built by attracting local technical high school graduates, and engineers from the colleges in the Northeast. RBC Bearings continues to build upon the strong relationship with these programs to grow the highly skilled workforce at the Engineered Components facility. Any inquires for products should be directed to the RBC - Heim Bearings company.

Products

Industrial Rod Ends, Heim® Bearings

Spherical Plain Rod Ends are used to carry a load and accommodate misalignment in various systems.

Rod Ends are used in a variety of applications, most common are:

- Packaging Equipment

- Material Handling

- Off road vehicles (ATV/UTV)

- Power Generation

- Solid Performance Raceway Material

- Low Friction

- Superior race to ball conformity

Journal Bearings, Heim® Bearings

Heim® Journal Bearings are designed in straight (plain) or flanged configurations to accommodate radial and/or axial load and oscillatory motion requirements.

Heim® Journal Bearings are used in a variety of applications, most common are:

- Packaging Equipment

- Material Handling

- Aircraft Passenger Door Actuation Systems

- Mechanical Lifts

- Light Weight / Compact Design

- Corrosion Resistant Materials

- Maintenance Free Self-Lubricating Liner System

- Extended Operating Life

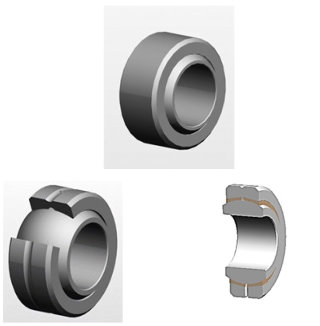

Spherical Plain Bearings, HEIM® Bearings

Heim® Spherical Bearings are designed in two piece or four piece configurations to accommodate angular misalignment, radial/axial load, and oscillatory motion.

Heim® Spherical Bearings are used in a variety of applications, most common are:

- Hydraulic actuators

- Articulated joints

- Power generation

- Vehicle steering linkages

- High load capacity

- Angular misalignment & rotation

- High alternating & shock load capacity

- Corrosion resistant materials

- Metal-to-metal or maintenance free self-lubricating

- Extended Operating Life

Location(s)

Locations (click on Directions):

Fairfield, Connecticut

60 Round Hill Road, Fairfield, CT 06824HeimRFQ@RBCBearings.com Phone: (203) 255-1512

Fax: (203) 319-7709