All Power Manufacturing Company

Contact Us

Send us a message

Note: Messages will be sent to All Power Manufacturing Company only

About All Power Manufacturing Company

Founded in 1938, All Power Manufacturing quickly established itself as an integral part of the fast-growing aerospace industry. All Power’s commitment to excellence early on leads to strong company growth. Soon, All Power positioned itself to be one of the largest manufacturers in the world of precision aerospace bushings, spacers, sleeves, and specialty parts.

Founded in 1938, All Power Manufacturing quickly established itself as an integral part of the fast-growing aerospace industry. All Power’s commitment to excellence early on leads to strong company growth. Soon, All Power positioned itself to be one of the largest manufacturers in the world of precision aerospace bushings, spacers, sleeves, and specialty parts.

Today, All Power provides quality products to the worldwide market. The primary products include bushings, spacers, machined components, including clevises, links, specialty pins/bolts, and structural assemblies.

All Power produces parts from materials such as stainless steels, aluminum, bronze/brass, beryllium copper, copper, aluminum-nickel-bronze, and more. All Power also has experience with more exotic materials such as Inconel®, titanium, and cobalt. Our fabrication specialties include CNC turning and milling, grinding, honing (up to 10 inches in diameter), special processes (zinc-nickel, cadmium, and chrome plating), and assembly operations.

Trademark Information

Inconel® is registered trademark of Inco Alloys International Inc., Corp. of Huntington West Virginia

Products

Flanged Bushings, AllPower

Flanged Bushings, also known as Shoulder Journal Bearings, come in a variety of standards and are commonly pressed into upper level assemblies to reduce friction & wear and tear. Common materials include 17-4PH CRES and Aluminum Nickel Bronze per AMS4640

Flanged Bushings have many applications, some of which include:

- Landing Gear

- Aircraft Passenger Doors

- Flight Control Mechanisms

- Clevises

- Links

- Reduces friction between two sliding surfaces (shaft to bushing) resulting in reduced wear and tear.

- Flanged Bushings are easily replaceable and a cost-effective way to protect expensive assemblies.

Straight Bushings, AllPower

Straight Bushings, sometimes called Journal Bearings or Sleeves, come in a variety of standards and are commonly pressed into upper level assemblies to reduce friction & wear and tear. Common materials include 17-4PH CRES and Aluminum Nickel Bronze per AMS4640

Straight Bushings have many applications, some of which include:

- Landing Gear

- Aircraft Passenger Doors

- Flight Control Mechanisms

- Clevises

- Links

- Reduces friction between two sliding surfaces (shaft to bushing) resulting in reduced wear and tear.

- Straight Bushings are easily replaceable and a cost-effective way to protect expensive assemblies.

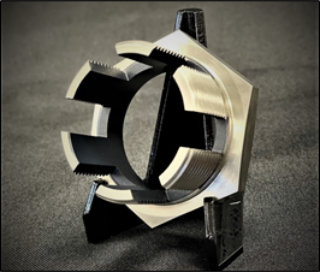

Custom Bushings, AllPower

Custom Bushings are built to the customer print (often source controlled drawings) and can be supplied with numerous features, including ID or OD lubrication grooves, cross holes, and threads.

Custom Bushings have many applications, some of which include:

- Landing Gear

- Engine Components

- Allowing the end-user to customize a bushing to exactly what they need.

- Can be provided in exotic, high temperature materials such as Inconel® 718, Titanium 6AL-4V, or Beryllium Copper.

- Can also have exotic finishes, including primers, paints, and various different coatings.

Trademark Information

Inconel® is registered trademark of Inco Alloys International Inc., Corp. of Huntington West Virginia

Rod End Body, AllPower

Rod End Bodies are the structural component of a Rod End Bearing and are manufactured by AllPower. They often have an circular bore at one end, where the bearing is inserted, and a threaded shaft on the other end.

AllPower can supply Rod End Bodies for a variety of applications, both Aerospace AND Industrial:

- Steering Links

- Tie Rods

- Aircraft Applications

- Gym Equipment

- Golf Carts

- Utilizing 5-Axis CNC mill-turn machining

- In house thread rolling

- In house plating

Clevises, AllPower

Clevises are another sub category of machined components that AllPower provides. They are similar to Rod End Bodies in that they often have a threaded shaft, but instead of having an single circular bore, they have a fork that has two circular holes which bushings are installed in.

Clevises are often used on:

- Rod Assemblies

- Control Rods

- Push-Pull Rods

- Struts

- Potential to provide next level assembly with bushings already pressed into clevis

Misc. Machined Components, AllPower

AllPower also provides miscellaneous machined components. There are many sub-categories of machined components.

Some examples of machined components we can provide are:

- Brackets

- Pins

- Housings

- Pistons

- Bellcranks

Location(s)

Locations (click on Directions):

Santa Fe Springs, California

13141 Molette Street, Santa Fe Springs, CA 90670AllPowerQuotes@RBCBearings.com Phone: (562) 802-2640

Fax: (562) 921-9933