Thin Section Ball Bearings Engineering Data

Thin Section Ball Bearings

For more details and a current listing of parts, please visit:

Product Info

Table of Contents

Thin Section Bearings Selection Guide

| Bearing Type |

Contact | Radial | Axial | Moment | Reversing Axial |

Combined Radial-Thrust |

|

| C | Radial | Excellent | Good | Good | Good | Good | |

| A | Angular | Good | Excellent | Do Not Use | Do Not Use | Good | |

| X | 4-Point | Poor | Good | Excellent | Excellent | Poor | |

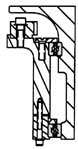

Angular Contact A-Type

Thin Section Ball Bearings

In applications with high axial loads the A-Type, angular contact ball bearing should be used. This bearing also works well in radial or combined radial-thrust applications. The A-Type bearing should never be used alone to support moment loads or reversing axial loading.

Two A-Type bearings are often used as a duplex pair. The three different configurations for duplex bearings are discussed in the Engineering Data section.

Radial Contact C-Type

Thin Section Ball Bearings

The C-Type, radial contact ball bearing is designed with deep ball grooves to withstand high loads. Although this bearing is used primarily in applications with radial loads, it can withstand moderate axial loads, reversing axial loads, and moment loads.

4-Point Contact X-Type

Thin Section Ball Bearings

The X-Type, or 4-point contact, ball bearing is ideal for moment loading. X-Type bearings are designed with gothic arch raceways creating 4 contact points between the balls and the raceways. This design is excellent for moment loading and reversing axial loading. The X-Type bearing can be used for other light loading conditions, but is not recommended in place of the C- or A-Type bearing for pure radial loads.

Engineering Data

The methods, equations, and technical data presented in this section allow the user to select the correct bearings and estimate their performance for a wide range of applications. For applications with severe or unusual operating conditions, RBC is prepared to provide an in-depth analysis and recommend the most suitable bearing arrangement.

Where standard bearings cannot be used, RBC can meet the application requirements with a special bearing design specifically tailored for optimum performance. Contact your RBC Sales Engineer for special sizes, materials, application requirements, dimensions and tolerances.

Capacity and Fatigue Life of Ball Bearings

The BASIC DYNAMIC RADIAL LOAD RATING, C, or "dynamic capacity", for a ball bearing is that calculated, constant radial load at which 90% of a group of apparently identical bearings with stationary outer rings can statistically endure 106 revolutions of the inner ring. ANSI/ABMA Standard 9 with correction factors for race curvatures was used to calculate the catalog ratings.

The DYNAMIC THRUST and DYNAMIC MOMENT LOAD RATINGS are also shown in the product tables. The ratings shown are a guide for the maximum loads under which these bearings should be operated with either pure thrust or pure moment loading. Thrust ratings are 2.5 to 3.0 times the radial ratings depending on the bearing type and cross section. These load ratings are not additive. For combined radial and thrust loads, an equivalent radial load is to be calculated.

The BASIC STATIC LOAD RATING, Co, or "static capacity", is that uniformly distributed load, which produces a maximum theoretical contact stress of 609,000 psi. At this contact stress permanent deformation of ball and raceway occurs. This deformation is approximately .0001% of the ball diameter.

The RATING LIFE, L10, is a statistical measure of the life which 90% of a large group of apparently identical ball bearings will achieve or exceed. For a single bearing, L10 also refers to the life associated with 90% reliability. Median Life, L50, is the life which 50% of the group of ball bearings will achieve or exceed. Median life is approximately five times the rating life.

The relationship between rating life, load rating, and load is:

L10 = (C/P)3 with L10 = rating life (106 rev)

C = basic dynamic radial load rating (lbf)

P = equivalent radial load (lbf)

To obtain the rating life in hours, use:

L10 hrs = 16667/n * (C/P)3 with n = speed (rpm)

The Equivalent Radial Load is defined as:

P = XFr + YFa with Fr = radial load (lbf)

Fa = axial load (lbf)

X = see below

Y = see below

Adjustment Factors for Rating Life

If a bearing design and operation deviates significantly from normal, it may be necessary to use additional factors to estimate the fatigue life Ln.

Ln = a1 * a2 * a3 * L10hrs

a1 = reliability factor

a2 = material & processing factor

a3 = application factor

Reliability Factor a1

Reliability is the percentage of a group of apparently identical ball bearings that is expected to attain or exceed a specified life. For an individual bearing it is the probability that the bearing will attain or exceed a specified life. Typical bearing lives are calculated for 90% reliability. The life adjustment factors for other reliability numbers are shown below.

| Reliability % | Ln | Reliability Factor a1 |

| 90 | L10 | 1.00 |

| 95 | L5 | .62 |

| 96 | L4 | .53 |

| 97 | L3 | .44 |

| 98 | L2 | .33 |

| 99 | L1 | .21 |

Material Factor a2

For standard bearings the material factor a2 is equal to 1.00. Factor a2 is determined by material processing, forming methods, heat treatment, and other manufacturing methods. Some commonly used material factors are listed below:

| Material, Condition | a2 max |

| 52100, Air melt | 1.00 |

| 52100, Vacuum degassed | 1.50 |

| 52100, Air melt & TDC Plate | 2.00 |

| 52100, Vacuum melt, (CEVM) | 3.00 |

| 440C, Air melt | 1.00 |

| 440C, Vacuum melt (CEVM) | 2.00 |

| M50, Vacuum melt (CEVM) | 5.00 |

| M50, Vacuum re-melt (VIM-VAR) | 8.00 |

Application Factor a3

The application factor a3 is equal to 1.0 for most applications. Unusual or extreme conditions in certain applications such as low speed, shock loading, vibration, and extreme temperature may lower the application factor to 0.50. Contact your RBC Sales Engineer for help in determining this factor for your special application.

Load and Speed Limitations

The load ratings shown in the product tables are not additive. For combined simultaneous loading, an equivalent radial or thrust load must be considered. In general, C-Type bearings are designed for radial loading applications; moderate thrust and/or moment loading may be applied in combination with radial loading. For thrust loading applications use the A-Type bearing; any radial loading should only be applied in combination with thrust loading. X-Type bearings are primarily for reversing thrust and moment loading, pure radial loading should not be applied.

The limiting speeds shown in the product tables are based on standard lubrication. The unsealed bearing speeds are calculated assuming the bearings are lubricated with MIL-L-3150. Limiting speeds for sealed bearings are calculated assuming the bearings are lubricated with MIL-G-23827 grease. If bearings are lubricated with alternate oils or greases, new limiting speeds must be calculated, see operating conditions.

Operating Conditions

Lubricants serve a number of very important purposes in ball bearings, including:

- protecting bearing surfaces from corrosion

- reducing rolling and sliding friction

- preventing metal-to-metal contact between balls and raceway

- providing a barrier against external contaminants (grease)

- removing heat (oil)

Lack of lubrication or inadequate lubrication is the most common cause of bearing failure.

Standard RBC Thin Section Ball Bearings are lubricated with either oil or grease. The unsealed bearings, the K series, are thoroughly coated in MIL-L-3150 oil and drained of excess. Sealed bearings are lubricated with MIL-G-23827 grease. The external surfaces of sealed bearings are lightly coated with the same grease for corrosion resistance. Additional lubricants are also available. Your RBC Sales Engineer can help select the appropriate lubricant for special applications.

Temperature

Standard RBC Thin Section Ball Bearings can operate at temperatures from -65°F to 250°F. Temperatures up to 350°F can be reached if the bearings are temperature stabilized. By the use of special materials RBC can provide bearings for operation to 700°F. Contact your RBC Sales Engineer for recommendations on bearings operating above 250°F.

Limiting Speed

The limiting speed of a bearing is dependent upon a number of different factors including bearing size, bearing type, ball separator design, lubrication and loading. The limiting speeds for the bearings shown in this catalog are determined using the following:

| Bearing Type | Load Condition | k Value | |

| Grease | Oil | ||

| C or A | Radial or Thrust | 16 | 20 |

| X | Thrust | 10 | 12 |

| X | Radial, Combined Radial & Thrust, or Moment |

3 | 4 |

The k values shown give the maximum speeds at which a typical thin section ball bearing can operate. It is recommended that operating speeds of large diameter bearings in a given series be reduced up to 40% of the calculated rating to avoid high bearing temperatures. Speed ratings can also be impacted by load conditions, lubrication, alignment and ambient temperature. All of these factors must be considered when designing thin section ball bearings into your application.

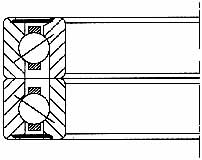

Duplex Pairs and Axial Preloading

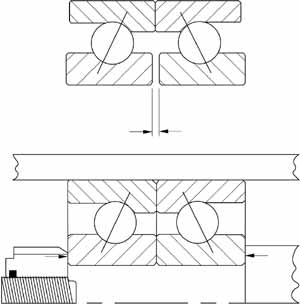

Duplex Pairs

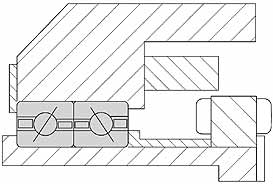

Duplex bearings are a pair of angular contact RBC Thin Section Ball Bearings specially ground for use as a matched set. A duplexed pair can be used to provide accurate shaft location, to increase capacity or to increase stiffness of the bearing assembly. A duplex pair of RBC Thin Section Ball Bearings is ground so that when mounted using recommended fits, there will be no internal clearance in the bearings. There are three basic mounting methods to accommodate different loading requirements:

- Back-to-Back (DB) B-Type

- Face-to-Face (DF) F-Type

- Tandem (DT), T-Type

Back-to-Back, DB

B-Type

- Heavy radial loads

- Combined thrust & radial loads

- Reversing thrust load

- Excellent rigidity

- Moment loads

Tolerances

Precision Grades

RBC Thin Section Ball Bearings are available in four precision grades. RBC Precision classes 0, 3, 4 and 6 correspond to ABMA ABEC grades 1F, 3F, 5F and 7F respectively. The tolerances for the bearing bores, outer diameters, radial runouts, axial runouts and radial plays are shown in the Tolerance Tables.

Shaft and Housing Fits

Proper shaft and housing fits are critical to the successful operation of a thin section ball bearing. The internal clearance of the bearing will be reduced proportionally by an interference fit. In addition, the roundness of the shaft and housing will directly affect the roundness of the inner and outer ring raceways. For most applications the inner ring is rotating and the load is stationary with respect to the outer ring. In this circumstance a light press fit onto the shaft is recommended. The recommended shaft and housing fits are shown in the Tolerance Tables.

Mounting Arrangements

When selecting a mounting arrangement for RBC Thin Section Ball Bearings, you must first consider the loading condition. A duplex pair of angular contact bearings may be used for combined loading, moment loading, or heavy thrust loading. Combination A and C-Type, A and X-Type, or C and X-Type bearings are common mounting arrangements. Two X-Type bearings should never be mounted on the same shaft. There may be many different bearing arrangements for carrying the same load, some typical mounting arrangements are shown below.

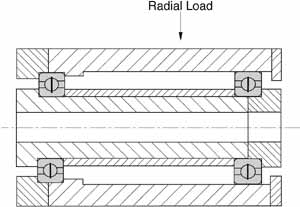

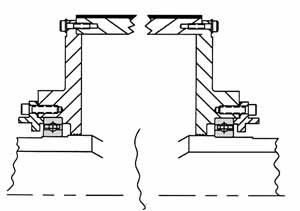

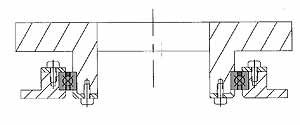

Heavy Radial Loads

The C-Type bearing is designed primarily for heavy radial loads. Two bearings can be installed on the same shaft as shown. By axially fixing one bearing and allowing the other to float, this configuration allows differential expansion between the housing and shaft, such as caused by temperature difference, without adding axial stress to the bearings. Although the C-Type bearing is designed for radial loads, they can withstand moderate thrust, moment and reversing loads.

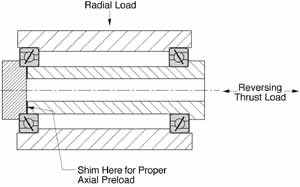

Reversing Loads

The duplex pair of A-Type bearings offers several configurations. For reversing loads, either back-toback, B-Type, or face-to-face, F-Type, should be used. The F-Type mounting method demonstrates reversing thrust load. Combined radial and thrust loads are shown on the B-Type configuration. Both of these methods can be used for heavy radial loads, combined thrust and radial loads, or moment loads.

B-Type Configuration

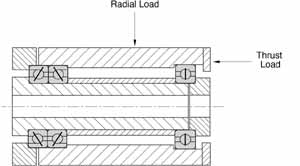

Heavy Combined Loading

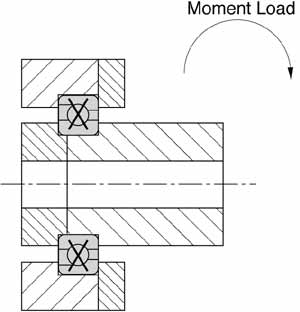

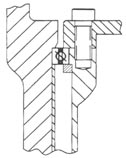

For heavy combined loading other special mounting arrangements may be employed. As shown in the top drawing, a duplex pair of A-Type bearings can be used with a floating C-Type bearing. In this configuration the A-Type bearings will carry the thrust load and part of the radial load while the C-Type carries only radial load. An X-Type bearing can replace the duplex pair of A-Type bearings to carry lower thrust loads as shown in the second drawing.

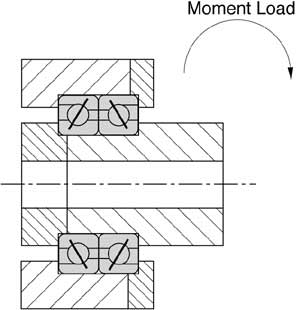

Heavy Combined Loading or Moment Loading

Alternate mountings for heavy combined loading or moment loading are shown below. A duplex pair of B-Type bearings resists high thrust, radial and moment loads. An X-Type bearing may replace the duplex pair in less heavily loaded applications for weight, space and cost savings.

Custom Features

RBC manufactures many custom bearings designed to optimize bearing performance for specific applications. Special features include changes in radial play, lubricants, materials, preloading and design. Contact your RBC Sales Engineer for your custom bearing needs.

Challenge us: There are many design options available to solve difficult application problems.

Materials

The standard bearings shown in the catalog have SAE 52100 steel rings and balls. RBC Thin Section Ball Bearings can be manufactured from other specialty bearing steels to provide corrosion resistance, high temperature capability, alternative load capacity or chemical compatibility.

Rings. RBC has manufactured thin section ball bearings from SAE 440C stainless steel to provide corrosion resistance. As an alternative to stainless steel rings, the entire surface of the rings can be plated with nodular thin dense chrome (TDC). This plating, which meets AMS 2438, achieves a molecular bond that will not flake, peel or separate from the base material. The TDC plate has a hardness of HRC 70 - 78 and can withstand temperatures well beyond the range of the base material.

Special RBC Thin Section Ball Bearings have been manufactured from Aluminum, 300 Series Stainless Steel, 17-4 Stainless Steel, and other metals.

Balls. Some special ball materials available include 440C Stainless Steel, 300 Series Stainless Steel, Silicon Nitride and M-50 Steel.

Lubrication

Many different lubricants are available from RBC for special applications. Greases which are designed specifically for high speed, low torque, water resistance, high temperature, oscillatory motion and food machinery can be provided. Additional lubricants, such as dry film, are suitable for use in vacuums and space applications.

Sealing

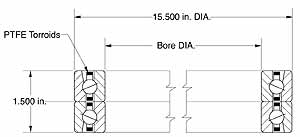

Standard seals for thin section ball bearings are molded from elastomers (Buna N). Polytetra-flouroethylene (PTFE) seals, fiber glass reinforced PTFE seals, stainless steel shields and many other options are available for low torque and other special applications.

Radial Play

The radial play (diametral clearance) of a thin section ball bearing will need to be predetermined if mounting fits other than those recommended are used. Special radial play may be required for a temperature differential across the bearing, for housing and shaft materials that have different coefficients of thermal expansion, or to change operating characteristics of the bearing. Radial preloaded bearings are measured to meet bore and O.D. tolerances prior to preload.

Preloading of Duplex Bearings

Standard duplex bearings are ground so that there will be a light axial preload induced on the bearing at nominal conditions. In some applications increased bearing stiffness may be required. In these cases the duplex grinding can be done such that a heavier axial load is induced in the mounted bearing. This load can be increased or decreased to meet the requirements of a particular application. Consult your RBC Sales Engineer for special requirements.

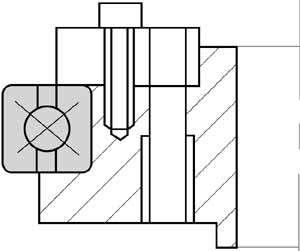

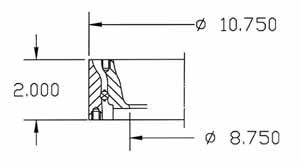

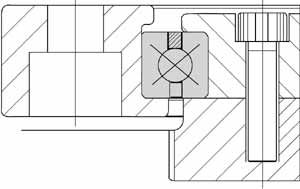

Mounting Features

Mounting features, such as flanges, anti-rotation tabs and mounting holes can be incorporated on the inner and outer rings. Mating parts, such as gears and housings, may be integrated into the bearing rings for improved performance and cost.

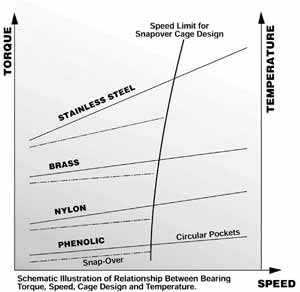

Separators

Standard RBC Thin Section Ball Bearings, KA through KG and JU series, are manufactured with brass separators. The KAA series contains nylon separators. The A-Type bearings contain one-piece circular pocket separators, while the C and X-Types have snap-over separators. The four basic separator materials are brass, nylon, phenolic and stainless steel. The graph below schematically illustrates the effects of cage design and material on bearing performance. Specific material advantages and limitations are listed on page 39. In comparison, the one-piece circular pocket design may reach roughly two times the speed of the snap-over design. Exact speed limits depend on bearing size, bearing type, lubrication and loading. For assistance in selecting the appropriate separator for special applications, contact your RBC Sales Engineer.

Typical Applications

Thin section ball bearings are generally used in applications with space, weight, and load constraints. Some typical applications for standard RBC Thin Section Ball Bearings include:

| Medical Equipment | Machine Tools |

| Radar Equipment | Textile Machinery |

| Material Handling | Satellite Systems |

| Antenna Equipment | Packaging Machinery |

| Aerospace | Scanning Equipment |

| Optical Equipment | Semi-Conductor |

| Rotary Joints | Manufacturing Equipment |

| Military Turrets | Slip Ring Assemblies |

| Robotics | >Harmonic Drives |

| Speed Reducers |

| Rotary Table Using a 4-point contact bearing provides high stiffness with minimum deflection resulting in a streamlined and lightweight design. |

|

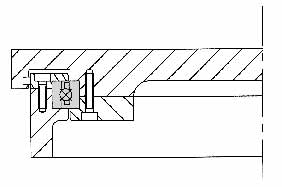

| Direct Drive Assembly A duplex pair of angular contact RBC Thin Section Ball Bearings provide the optimal load carrying capabilities in a compact design. |

|

| Lightweight Airborne Electro-Optical Imaging Equipment This application requires bearings with combined load carrying capabilities and minimal added weight. A pair of angular contact RBC Thin Section Ball Bearings provides high stiffness and multiple load carrying capabilities in a compact, lightweight envelope. |

|

| Paper Making Machine A pair of radial contact RBC Thin Section Ball Bearings is the ideal choice for applications with severe space constraints and significant loads. |

|

| Rotating Polishing Table To provide necessary stiffness with a more compact, lighter weight machine design, use the 4-point contact RBC Thin Section Ball Bearing. |

|

| Rotary Joint By using a pair of angular contact RBC Thin Section Ball Bearings, this design can carry radial, axial and moment loads. |

|

Custom Bearing

In addition to the standard RBC Thin Section Ball Bearings, RBC will also manufacture specially designed bearings for specific applications. RBC Sales Engineers and Customer Service Representatives are available for consultation.

Continuous Rotating Machine

Tool Table Using a 4-point contact RBC Thin Section Ball Bearing provides stiffness for accurate positioning as well as carrying multiple loads. RBC supplied this assembly as shown.

Aerial Camera Assembly

For use in an aerial camera assembly, an extra-light, low torque bearing was required. By redesigning a standard RBC Thin Section Ball Bearing 4-point contact design, the overall assembly weight was lowered from 7 lbs. to 3.8 lbs. In addition to weight reduction, this design, also reduced the running torque below 1 in.-lbs. with the starting torque below 2 in.-lbs.

Machine Tool Indexing Table

Running at slow speeds with combined load carrying capabilities and minimal space determined the use of this 4-point RBC Thin Section Ball Bearing. RBC supplied this assembly as shown.

Airborne Radar System

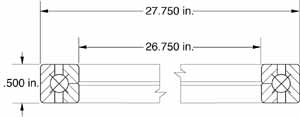

A duplex pair of angular contact RBC Thin Section Ball Bearings was designed for an airborne radar system. This bearing application required combined load carrying capabilities, low temperature compatibility, and relatively low torque. Different from a standard Thin Section, this duplex bearing was designed with one outer ring and two inner rings with a slight preload. This design provided low torque and multiple loading capabilities.

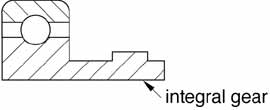

Radar Antenna Drive

An RBC Thin Section Ball Bearing designed with a gear integrated with the inner ring, achieved both a significant weight reduction and improved accuracy as well as simplicity of assembly. This bearing is used in a radar antenna drive which has limited space available for its support bearing. Coil springs were used as spacers between balls to lower bearing torque and further reduce weight.

Instrument Gimbal Assembly

A preloaded duplex pair of angular contact RBC Thin Section Ball Bearings were designed to meet the low torque and corrosion resistant requirements in a combined load application. Designed for an instrument gimbal assembly in a missile, the duplex pair of bearings are subjected to combined radial, axial, and moment loads. These special RBC Thin Section Ball Bearings have a light preload and were manufactured with integral shields as part of the rings.

Vacuum Operation

Bearing requirements included minimal radial runout, low torque, corrosion resistance, combined load capabilities and vacuum operation capabilities. Special designed duplex stainless steel angular contact RBC Thin Section Ball Bearings, provided the capabilities required.

Aircraft Gun Turret

A bearing was required which would take radial, axial, and moment loading, to support an aircraft gun turret. It was desirable to have a bearing match the coefficient of expansion of the aluminum with a split inner ring and special balls to absorb shock and vibration loading. This bearing performed at 25% of the torque of the steel bearings previously used.

Semiconductor Automated Test Equipment

Semiconductor automated test equipment required an RBC Thin Section Ball Bearing to accurately position a table. In this application the bearing oscillates to ± 10 degrees, and was designed as a 4-point contact bearing.

Airborne Turret Azimuth

A low torque, high stiffness, multiple load capacity, corrosion resistant bearing was required for an airborne turret azimuth drive assembly. For this application a duplex pair of angular contact RBC Thin Section Ball Bearings was designed with toroid separators and stainless steel rings. This design maintained low torque, but still allowed multiple load carrying capabilities.

Tolerance Tables

ABEC 1F X-TYPE

RBC PRECISION CLASS 0

| Bearing Bore Size (Inches) |

Diameter | Race Runout Radial & Axial | |||

| Bore Nominal | O.D. Nominal | Inner Max | Outer Max | Width Nominal | |

| 1.00 | -4 | -5 | 5 | 8 | -50 |

| 1.50 | -5 | -5 | 6 | 8 | -50 |

| 2.00 | -6 | -5 | 8 | 10 | -50 |

| 2.50 | -6 | -5 | 8 | 10 | -50 |

| 3.00 | -6 | -6 | 8 | 10 | -50 |

| 3.50 | -8 | -6 | 10 | 12 | -50 |

| 4.00 | -8 | -6 | 10 | 12 | -50 |

| 4.25 | -8 | -8 | 10 | 14 | -50 |

| 4.50 | -8 | -8 | 10 | 14 | -50 |

| 4.75 | -10 | -8 | 12 | 14 | -50 |

| 5.00 | -10 | -8 | 12 | 14 | -50 |

| 5.50 | -10 | -10 | 12 | 16 | -50 |

| 6.00 | -10 | -10 | 12 | 16 | -50 |

| 6.50 | -10 | -10 | 12 | 16 | -50 |

| 7.00 | -10 | -10 | 12 | 16 | -50 |

| 7.50 | -12 | -12 | 16 | 18 | -50 |

| 8.00 | -12 | -12 | 16 | 18 | -50 |

| 9.00 | -12 | -12 | 16 | 18 | -50 |

| 10.00 | -14 | -14 | 18 | 20 | -50 |

| 11.00 | -14 | -14 | 18 | 20 | -50 |

| 12.00 | -14 | -14 | 18 | 20 | -50 |

| 14.00 | -16 | -16 | 18 | 20 | -100 |

| 16.00 | -18 | -18 | 18 | 20 | -100 |

| 18.00 | -18 | -18 | 20 | 20 | -100 |

| 20.00 | -20 | -20 | 20 | 20 | -100 |

| 25.00 | -30 | -30 | 20 | 20 | -100 |

| 30.00 | -30 | -30 | 20 | 20 | -100 |

| 35.00 | -40 | -40 | 20 | 20 | -100 |

| 40.00 | -40 | -40 | 20 | 20 | -100 |

ABEC 1F X-TYPE

RBC PRECISION CLASS 0

| Bearing Bore Size Inches | Diameter | Race Runout Radial & Axial | |||

| Bore Nominal | O.D. Nominal | Inner Max | Outer Max | Width Nominal | |

| 1.00 | -4 | -5 | 3 | 4 | -50 |

| 1.50 | -5 | -5 | 4 | 4 | -50 |

| 2.00 | -6 | -5 | 5 | 5 | -50 |

| 2.50 | -6 | -5 | 5 | 5 | -50 |

| 3.00 | -6 | -6 | 6 | 6 | -50 |

| 3.50 | -8 | -6 | 6 | 6 | -50 |

| 4.00 | -8 | -6 | 6 | 6 | -50 |

| 4.25 | -8 | -8 | 6 | 8 | -50 |

| 4.50 | -8 | -8 | 6 | 8 | -50 |

| 4.75 | -10 | -8 | 8 | 8 | -50 |

| 5.00 | -10 | -8 | 8 | 8 | -50 |

| 5.50 | -10 | -10 | 10 | 10 | -50 |

| 6.00 | -10 | -10 | 10 | 10 | -50 |

| 6.50 | -10 | -10 | 10 | 10 | -50 |

| 7.00 | -10 | -12 | 10 | 10 | -50 |

| 7.50 | -12 | -12 | 12 | 12 | -50 |

| 8.00 | -12 | -12 | 12 | 12 | -50 |

| 9.00 | -12 | -12 | 12 | 12 | -50 |

| 10.00 | -14 | -14 | 14 | 14 | -50 |

| 11.00 | -14 | -14 | 14 | 14 | -50 |

| 12.00 | -14 | -14 | 14 | 14 | -50 |

| 14.00 | -14 | -14 | 14 | 14 | -100 |

| 16.00 | -16 | -16 | 16 | 16 | -100 |

| 18.00 | -16 | -16 | 16 | 16 | -100 |

| 20.00 | -18 | -18 | 18 | 18 | -100 |

| 25.00 | -18 | -18 | 18 | 18 | -100 |

| 30.00 | -18 | -18 | 18 | 18 | -100 |

| 35.00 | -20 | -20 | 20 | 20 | -100 |

| 40.00 | -20 | -20 | 20 | 20 | -100 |

| Bearing Radial Play Before Installation | Rotating Shaft | Stationary Shaft | |||||

| Min | Max | Shaft OD Nominal | Housing ID Nominal | Shaft OD | Housing ID | ||

| Max | Min | Max | Min | ||||

| 10 | 15 | 4 | 5 | -4 | -8 | -5 | -10 |

| 12 | 17 | 5 | 5 | -5 | -10 | -5 | -10 |

| 12 | 22 | 6 | 5 | -6 | -12 | -5 | -10 |

| 12 | 22 | 6 | 5 | -6 | -12 | -5 | -10 |

| 12 | 22 | 6 | 6 | -6 | -12 | -6 | -12 |

| 16 | 26 | 8 | 6 | -8 | -16 | -6 | -12 |

| 16 | 26 | 8 | 6 | -8 | -16 | -6 | -12 |

| 16 | 26 | 8 | 8 | -8 | -16 | -8 | -16 |

| 16 | 26 | 8 | 8 | -8 | -16 | -8 | -16 |

| 20 | 30 | 10 | 8 | -10 | -20 | -8 | -16 |

| 20 | 30 | 10 | 8 | -10 | -20 | -8 | -16 |

| 20 | 30 | 10 | 10 | -10 | -20 | -10 | -20 |

| 20 | 30 | 10 | 10 | -10 | -20 | -10 | -20 |

| 20 | 30 | 10 | 10 | -10 | -20 | -10 | -20 |

| 20 | 30 | 10 | 12 | -10 | -20 | -12 | -24 |

| 24 | 34 | 12 | 12 | -12 | -24 | -12 | -24 |

| 24 | 34 | 12 | 12 | -12 | -24 | -12 | -24 |

| 24 | 34 | 12 | 12 | -12 | -24 | -12 | -24 |

| 28 | 38 | 14 | 14 | -14 | -28 | -14 | -28 |

| 28 | 38 | 14 | 14 | -14 | -28 | -14 | -28 |

| 28 | 38 | 14 | 14 | -14 | -28 | -14 | -28 |

| 28 | 38 | 14 | 14 | -14 | -28 | -14 | -28 |

| 32 | 42 | 16 | 16 | -16 | -32 | -16 | -32 |

| 32 | 42 | 16 | 16 | -16 | -32 | -16 | -32 |

| 36 | 46 | 18 | 18 | -18 | -36 | -18 | -36 |

| 36 | 46 | 18 | 18 | -18 | -36 | -18 | -36 |

| 36 | 46 | 18 | 18 | -18 | -36 | -18 | -36 |

| 40 | 50 | 20 | 20 | -20 | -40 | -20 | -40 |

| 40 | 50 | 20 | 20 | -20 | -40 | -20 | -40 |

ABEC 3F ALL TYPES

RBC PRECISION CLASS 3

| Bearing Bore Size (Inches) |

Diameter | Race Runout Radial & Axial | |||

| Bore Nominal | O.D. Nominal | Inner Max | Outer Max | Width Nominal | |

| 1.00 | -2 | -3 | 3 | 4 | -50 |

| 1.50 | -3 | -3 | 4 | 4 | -50 |

| 2.00 | -4 | -4 | 4 | 5 | -50 |

| 2.50 | -4 | -4 | 4 | 5 | -50 |

| 3.00 | -4 | -4 | 4 | 6 | -50 |

| 3.50 | -5 | -4 | 5 | 6 | -50 |

| 4.00 | -5 | -4 | 5 | 6 | -50 |

| 4.25 | -5 | -5 | 5 | 8 | -50 |

| 4.50 | -5 | -5 | 5 | 8 | -50 |

| 4.75 | -6 | -5 | 6 | 8 | -50 |

| 5.00 | -6 | -5 | 6 | 8 | -50 |

| 5.50 | -6 | -6 | 6 | 9 | -50 |

| 6.00 | -6 | -6 | 6 | 9 | -50 |

| 6.50 | -6 | -6 | 6 | 9 | -50 |

| 7.00 | -6 | -7 | 6 | 10 | -50 |

| 7.50 | -7 | -7 | 8 | 10 | -50 |

| 8.00 | -7 | -7 | 8 | 10 | -50 |

| 9.00 | -7 | -7 | 8 | 10 | -50 |

| 10.00 | -8 | -8 | 10 | 12 | -50 |

| 11.00 | -8 | -8 | 10 | 12 | -50 |

| 12.00 | -8 | -9 | 10 | 14 | -50 |

| 14.00 | -8 | -9 | 12 | 14 | -100 |

| 16.00 | -9 | -10 | 14 | 16 | -100 |

| 18.00 | -9 | -10 | 14 | 16 | -100 |

| 20.00 | -10 | -12 | 16 | 18 | -100 |

ABEC 1F X-TYPE

RBC PRECISION CLASS 0

| Bearing Radial Play Before Installation | Rotating Shaft | Stationary Shaft | |||||

| Min | Max | Shaft OD Nominal | Housing ID Nominal | Shaft OD | Housing ID | ||

| Max | Min | Max | Min | ||||

| 5 | 9 | 2 | 2 | -2 | -4 | -2 | -4 |

| 5 | 9 | 2 | 2 | -2 | -4 | -2 | -4 |

| 5 | 9 | 3 | 3 | -3 | -6 | -3 | -6 |

| 5 | 9 | 3 | 3 | -3 | -6 | -3 | -6 |

| 6 | 12 | 3 | 3 | -3 | -6 | -3 | -6 |

| 6 | 12 | 3 | 3 | -3 | -6 | -3 | -6 |

| 6 | 12 | 3 | 3 | -3 | -6 | -3 | -6 |

| 8 | 14 | 3 | 4 | -3 | -6 | -4 | -8 |

| 8 | 14 | 3 | 4 | -3 | -6 | -4 | -8 |

| 8 | 14 | 4 | 4 | -4 | -8 | -4 | -8 |

| 8 | 14 | 4 | 4 | -4 | -8 | -4 | -8 |

| 10 | 16 | 4 | 5 | -4 | -8 | -5 | -10 |

| 10 | 16 | 4 | 5 | -4 | -8 | -5 | -10 |

| 10 | 16 | 4 | 5 | -4 | -8 | -5 | -10 |

| 10 | 16 | 4 | 5 | -4 | -8 | -5 | -10 |

| 10 | 16 | 5 | 5 | -5 | -10 | -5 | -10 |

| 10 | 16 | 5 | 5 | -5 | -10 | -5 | -10 |

| 10 | 16 | 5 | 5 | -5 | -10 | -5 | -10 |

| 10 | 16 | 5 | 5 | -5 | -10 | -5 | -10 |

| 10 | 16 | 5 | 5 | -5 | -10 | -5 | -10 |

| 12 | 18 | 5 | 6 | -5 | -10 | -6 | -12 |

| 12 | 18 | 6 | 6 | -6 | -12 | -6 | -12 |

| 14 | 20 | 6 | 7 | -6 | -12 | -7 | -14 |

| 14 | 20 | 6 | 7 | -6 | -12 | -7 | -14 |

| 14 | 22 | 7 | 8 | -7 | -14 | -8 | -16 |

ABEC 7F ALL TYPES

RBC PRECISION CLASS 6

| Bearing Bore Size Inches | Diameter | Race Runout Radial & Axial | |||

| Bore Nominal | O.D. Nominal | Inner Max | Outer Max | Width Nominal | |

| 1.00 | -2 | -2 | 2 | 2 | -50 |

| 1.50 | -2 | -2 | 2 | 2 | -50 |

| 2.00 | -2 | -2 | 2 | 2 | -50 |

| 2.50 | -2 | -2 | 2 | 2 | -50 |

| 3.00 | -2 | -3 | 2 | 2 | -50 |

| 3.50 | -3 | -3 | 2 | 2 | -50 |

| 4.00 | -3 | -3 | 2 | 2 | -50 |

| 4.25 | -3 | -4 | 2 | 3 | -50 |

| 4.50 | -3 | -4 | 2 | 3 | -50 |

| 4.75 | -3 | -4 | 3 | 3 | -50 |

| 5.00 | -3 | -4 | 3 | 3 | -50 |

| 5.50 | -3 | -4 | 3 | 3 | -50 |

| 6.00 | -3 | -4 | 3 | 3 | -50 |

| 6.50 | -3 | -4 | 3 | 3 | -50 |

| 7.00 | -3 | -4 | 3 | 4 | -50 |

| 7.50 | -4 | -4 | 3 | 4 | -50 |

| 8.00 | -4 | -4 | 3 | 4 | -50 |

| 9.00 | -4 | -4 | 3 | 4 | -50 |

| 10.00 | -5 | -5 | 4 | 4 | -50 |

| 11.00 | -5 | -5 | 4 | 4 | -50 |

| 12.00 | -5 | -5 | 4 | 5 | -50 |

| 14.00 | -5 | -6 | 4 | 5 | -100 |

Shop Now!

Shop Now!